We can rebuild her. We have the technology. We can make her better than she was. Better…stronger…faster.

Here are some general notes for how we can rebuild our makerbot. I’m calling this Project Leeloo – to rebuild her better than she was. Just a handful of things that Ive been thinking about and for the moment believe would be a good idea to incorporate into our rebuild, making our lives, and our prints, oh so much better.

Mendel inspired XY carriage

Thing 4213 gives us a printable replacement carriage using ball bearings over bushings. Should make things more stable, more efficient, quieter, and cleaner.

Thing 4213 gives us a printable replacement carriage using ball bearings over bushings. Should make things more stable, more efficient, quieter, and cleaner.

Minimal X rod mount

Thing 6884 is one of numerous x rod mounting blocks that secure the x rods to the case. I’m not so sure about the nuts not being fully 100% captive but its worth a shot. There are also x rod mounts in the following.

Thing 6884 is one of numerous x rod mounting blocks that secure the x rods to the case. I’m not so sure about the nuts not being fully 100% captive but its worth a shot. There are also x rod mounts in the following.

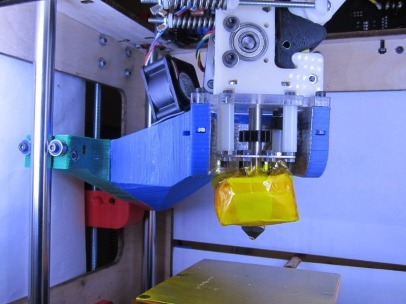

MiseryBot Z rider

Thing 7954 is an entirely new replacement z axis that will once and for all rid us of the dreaded z wobble. It uses beefy 12mm rods and more ball bearings although Im a little worried about the plastic that close to the heater core.

Thing 7954 is an entirely new replacement z axis that will once and for all rid us of the dreaded z wobble. It uses beefy 12mm rods and more ball bearings although Im a little worried about the plastic that close to the heater core.

Yet another extruder

There has to be a solution to our extruder problems: filament drags, the plunger works itself loose, thicker filament is spit back out like green beans, and its hard to clean. Thing 7113 attempts to fix this using ball bearings (see a trend?) and Thing 7564 modifies this for the mk4/5 dc gear motor. Why dc motor? Because while I know the print quality is worlds better until I can get around to redesigning the electrical system Im not so interested in using the gen 4 electronics on the cupcake. Edit: Here are some other files worth a look at: Thing 6402 and 6492.

There has to be a solution to our extruder problems: filament drags, the plunger works itself loose, thicker filament is spit back out like green beans, and its hard to clean. Thing 7113 attempts to fix this using ball bearings (see a trend?) and Thing 7564 modifies this for the mk4/5 dc gear motor. Why dc motor? Because while I know the print quality is worlds better until I can get around to redesigning the electrical system Im not so interested in using the gen 4 electronics on the cupcake. Edit: Here are some other files worth a look at: Thing 6402 and 6492.

Arguably that is probably more printing than a new Mendel but we wouldn’t be doing this if it was easy!

Filed under: Build, Mechanical, Things